- Home

- Products

- About us

- Download Center

- News

- Stock

- Contact

Product Advantages:

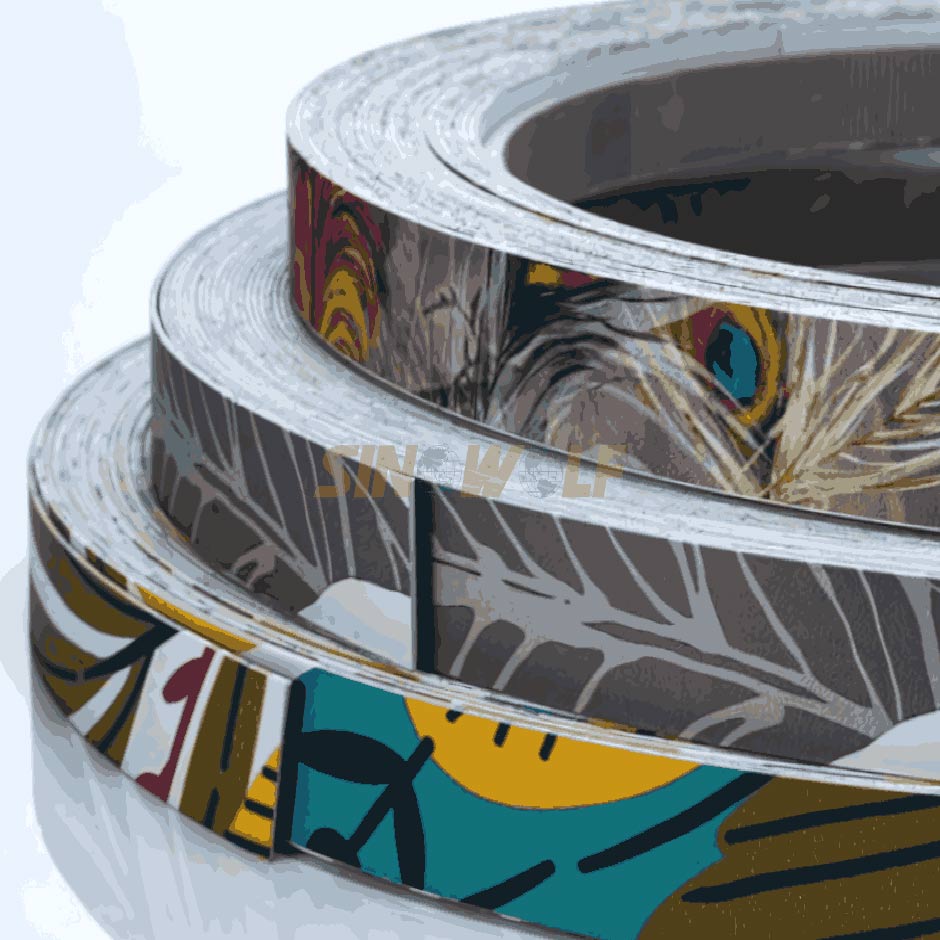

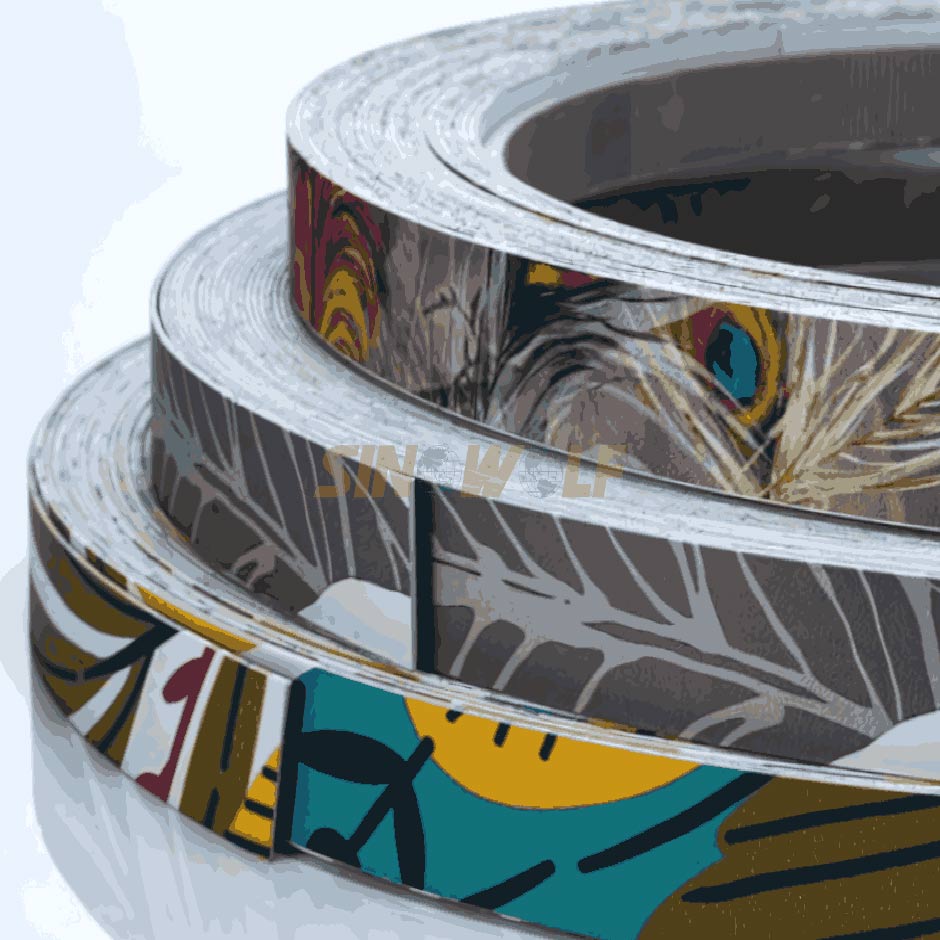

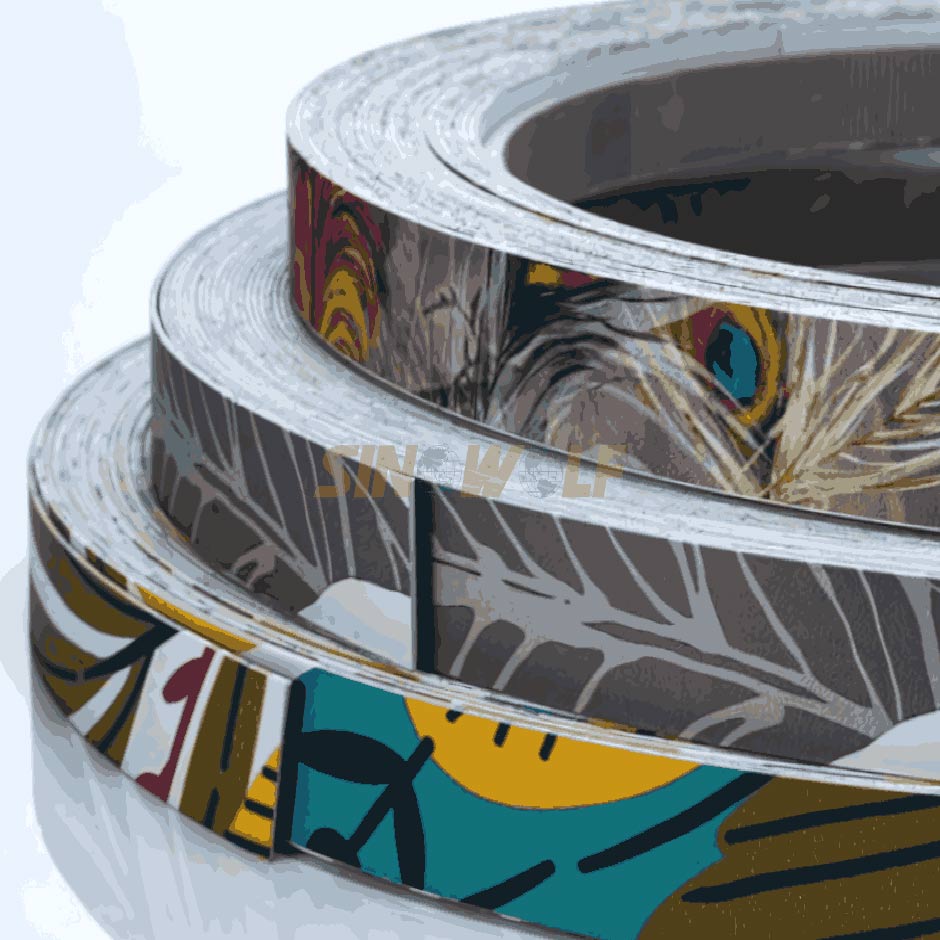

1. Sinowolf digital printed edge banding, clear color, delicate texture, abundant colors.

2. Sinowolf technology research& development, product iteration, always walk in the forefront of market. Sinowolf has its own digital design center and printing equipment, you can design according to your panel surface, and print the edge design directly, high production efficiency, showing up to what you see is what you get.

3. Sinowolf digital printed edge banding can enjoy the customized service, any logo, graphics, as long as the design draft, not only designers, customers can also provide the desired picture, DIY, to achieve the infinite possibility of edging.

Scope of application: Used in panel furniture, edging and surface define in the interior decoration.

Methods of use: 140-220 °C of hot melt glue in semi-automatic or fully-automatic edge bander.

| Specification List | ||

| ltem | Range | Tolerance range |

| Width | 12~20mm | ±0.5mm |

| 21~54mm | -0.2,+0.8mm | |

| Thickness | 0.4~0.7mm | +0.05mm |

| 0.8~1.5mm | ±0.1mm | |

| 1.6~2.0mm | ±0.15mm | |

| 2.1~3.0mm | ±0.2mm | |

| Surface gloss | 5~30° | -3°,+5° |

| 31~90 | -3°,+5° | |

| Meters/Roll | S100m | ±0.5mm |

| 100~300m | ±0.8mm | |

| Note: The size details of profile series can be negotiated and confirmed by both parties. | ||

Applications of Digital Edge Banding

1. Furniture Manufacturing

Digital edge banding is widely used in the production of furniture, such as tables, cabinets, chairs, and shelving. By providing smooth and seamless edges, it enhances both the aesthetics and durability of furniture products. Manufacturers can customize the edges in terms of material, color, and texture, allowing for various design finishes that appeal to different consumer tastes.

2. Cabinetry and Kitchen Units

In the kitchen industry, cabinetry requires precision and durability due to heavy usage. Digital edge banding ensures the edges of kitchen cabinets, drawers, and countertops are protected from moisture, wear, and impact. Its seamless application makes it suitable for modern and minimalist kitchen designs, where precision in every detail is key.

3. Office and Commercial Furniture

Edge banding is crucial in the production of office desks, conference tables, and shelving units. The digital process allows for mass customization, ensuring that office furniture has high-quality, durable edges that match corporate branding or design preferences. Digital edge banding also increases the lifespan of commercial furniture by protecting it from chipping and damage in high-traffic areas.

4. Interior Design and Custom Millwork

Interior designers often specify custom millwork, including wall panels, architectural details, and bespoke furniture pieces. Digital edge banding helps achieve clean, crisp edges on custom woodwork, making it a favored solution for creating high-end, polished interior finishes. It enables more intricate designs and precise color matching with surrounding decor.

5. Retail Displays and Fixtures

In the retail industry, display fixtures and point-of-sale units often feature digital edge banding. This enhances their aesthetic appeal and ensures durability in a commercial setting. The smooth and resistant edges created through this process make retail displays more professional and long-lasting.

6. Door and Panel Manufacturing

Digital edge banding is crucial for the production of interior doors, wardrobe panels, and other large flat surfaces. It provides an even and protective finish, preventing warping or cracking over time. This technique is commonly used in residential and commercial building materials, especially when durable, easy-to-clean edges are required.

FAQ:

High-quality, solid-color edging enhances the beauty of furniture by providing a smooth, finished edge appearance, hiding the raw edges of panels for a more polished appearance.

Edge banding is available in a variety of solid colors to match or complement different furniture designs and styles.

Installation typically requires basic tools such as cutters and applicators to ensure safe and precise application.

High-quality, solid-color edging tape is generally preferred over other options for its consistent color, durability, and ease of use.