- Home

- Products

- About us

- Download Center

- News

- Stock

- Contact

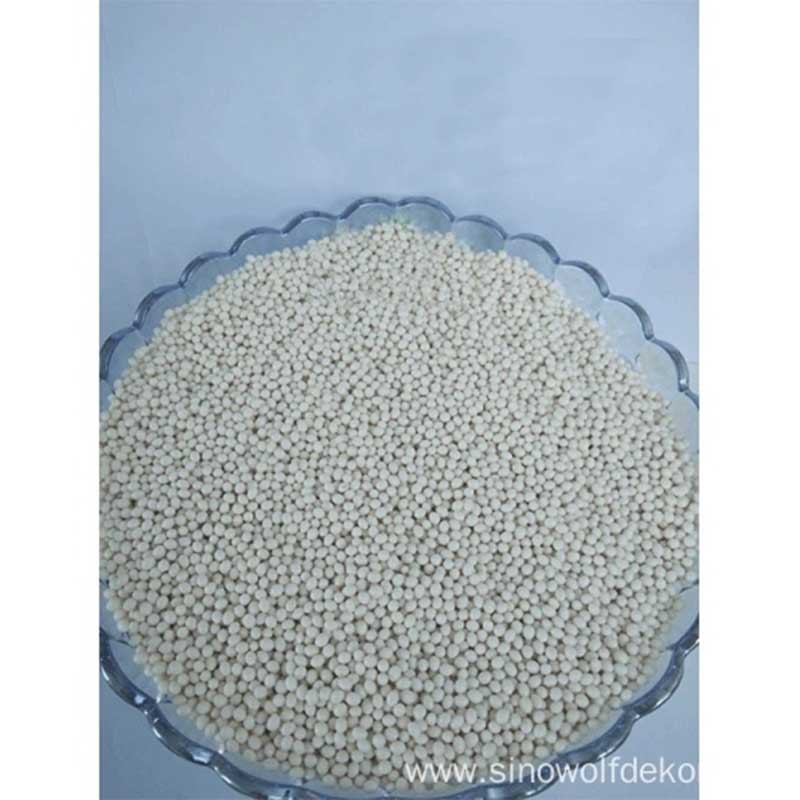

EVA glue is a type of adhesive that becomes liquid when heated and solidifies quickly when cooled. It is widely used in various industries due to its fast bonding speed and strong adhesion.

Hotmelt glue can bond different materials such as paper, plastic, wood, and metal. It is applied using a hot glue gun or in industrial processes through specialized equipment. It offers convenience and versatility in bonding applications.

bond different materials such as paper, plastic, wood, and metal. It is applied using a hot glue gun or in industrial processes through specialized equipment. It offers convenience and versatility in bonding applications.

High temperature: 190-210 ℃

Mid-temperature: 160-180 ℃

Low-temperature : 120-150 ℃

| Product Attributes | |||

| Model No. | HMG-01 | ||

| I Supply Ability & Additional Information | |||

| Packaging | Bag | Productivity | 50 container/month |

| Transportation | Ocean,Land | Place of Origin | Dongguan,CHINA(mainland) |

| Supply Ability | 50 container/month | Payment Type | L/C,T/T |

| Incoterm | FOB,CFR | ||

| Packaging & Delivery | |

| Selling Units | Kilogram |

| Package Type | Bag |

Edge Banding Hot Melt Adhesive Glue Low Temperature has the following advantages:

Low temperature operation: Due to its ability to operate at lower temperatures, it is particularly suitable for temperature sensitive materials or products.

Rapid curing: Hot melt adhesive can cure quickly, thereby improving production efficiency.

Water resistance and chemical resistance: This adhesive has good water and chemical resistance, allowing it to maintain good adhesion performance in various environments.

Easy to use: Hot melt adhesive is easy to use, just heat it up and apply it to the surface that needs to be bonded.

Wide applicability: can be used for various materials such as wood, plastic, glass, etc.

Good mechanical properties: with high strength, high elasticity, high wear resistance and other mechanical properties.

Environmental protection: It belongs to green and environmentally friendly materials, and waste can be recycled and reused.

Economy: Compared to other types of adhesives, hot melt adhesives have lower costs and higher economic benefits.

Advantages of our company's products - Hot Melt Glue:

1.Hot melt adhesive:high temperature, medium temperature, low temperature.

2.Excellent quality assurance, strong viscosity.

3.Stable color and quality between different lots.

FAQ:

Suppliers can be found on search engines, chemical product procurement websites, or related industry exhibitions.

Low temperature hot melt adhesive is superior to many other adhesives in terms of low temperature operation, rapid curing, good water resistance, and chemical resistance.

Hot melt adhesives with different temperature levels have different melting points, curing rates, and viscosities, and it is necessary to choose the appropriate level of hot melt adhesive based on specific application scenarios and materials.

Prices may vary depending on brand, model, and supplier. It is recommended to contact multiple suppliers for comparison.

Suitable for bonding various materials in furniture, wood processing, packaging, automotive, and construction industries.

The processing temperature is usually between 120 and 180 ° C, depending on the type of hot melt adhesive and the supplier's recommendations.

Low temperature hot melt adhesive can provide strong and long-lasting adhesion, and has excellent bonding strength for wood composite materials.

Low temperature hot melt adhesive is often considered a more environmentally friendly choice because it does not contain solvents and waste can be recycled and reused.

Usually, it only takes a few seconds to a few minutes, depending on the type and application conditions of the hot melt adhesive.

The curing temperature is usually between 80-120 ° C, and the curing time may range from a few seconds to a few minutes.

Low temperature hot melt adhesive usually has a lower viscosity, making it easy to apply and cover the surface of materials.

Low temperature hot melt adhesive usually has good moisture resistance and can maintain stable bonding strength in humid environments.

During the operation, it is necessary to avoid direct contact with the skin and inhalation of steam. It is recommended to use protective gloves and respirators, and ensure good ventilation in the workplace.

| Product Attributes | |||

| Model No. | HMG-01 | ||

| I Supply Ability & Additional Information | |||

| Packaging | Bag | Productivity | 50 container/month |

| Transportation | Ocean,Land | Place of Origin | Dongguan,CHINA(mainland) |

| Supply Ability | 50 container/month | Payment Type | L/C,T/T |

| Incoterm | FOB,CFR | ||

| Packaging & Delivery | |

| Selling Units | Kilogram |

| Package Type | Bag |